Aeration equipment, provide homogenous mixing of wastewater coming to aeration pools and provide oxygen needed for bacterial life. There are two different kinds of aerators.

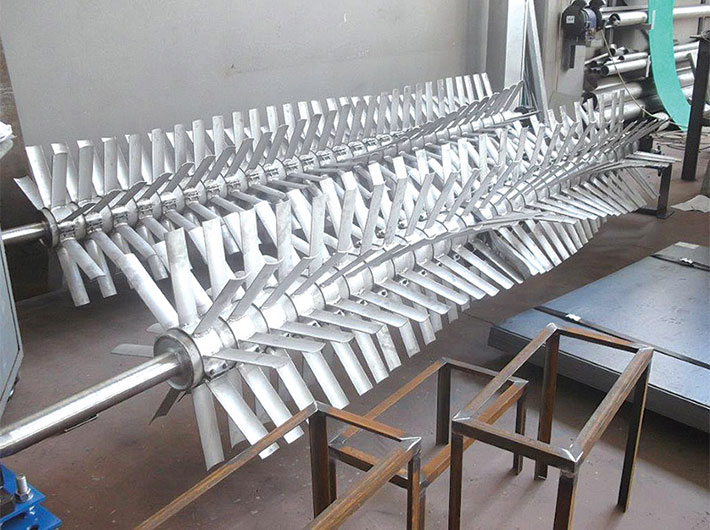

Aerators With Horizontal Shaft

They are used in aeration pools in wastewater treatment facilities. They are designed to provide oxygen needed for bacterial life in aeration pools.

It is mostly used in the oxidation ditch.

They consist of main shaft, blades and driving group. Protection against splashing water is performed on the connection couplings of the Aerators.

Aerators With Vertical Shaft

They are used in aeration pools in wastewater treatment facilities. They are designed to provide oxygen needed for bacterial life in aeration pools.

Aerators having vertical shaft, are manufactured in different capacities, according to oxygen needs of the system.

Aerators having vertical shaft, are designed in two categories: The pools having fixed water level and the pools having variable pool level. We mount fixed bridges on the pools having fixed water level.

Aerators are mounted with ponton systems on the pools having variable water level.

The capacity of the aerators increases linearly with motor power.

Aerators are manufactured between 1, 1 – 110 kW. They consist of spindle, coupling, fan and driving group.

Jet Aerators

Jet aerators give oxygen needed in the biological treatment facilities which are constructed to treat the municipal and industrial wastewater. Jet aerotors are more preferable than its equivalents of brush aerator, surface aerator and blower-diffuser systems in our country.

The Ministry of Environment and Urban Planning(former The Ministry of Environment and Forestry) prefers mostly jet aerators as ventilation equipment in typical projects. Jet aerator (aerojet type) has advantages of low energy consumption, low operating costs and maintainability. That’s why It is more efficient than its equivalents.

The Advantages of The JET Aerators

- Energy Consumption

- Operational Convenience and Maintainability

- Mounting Convenience

- Domestic Production Options

- Oxygen efficiency : 1, 5-2, 0 kg O2 / kWh