The aim of the Sludge dewatering system is to reduce the amount of water in sludge. Sludge coming to Sludge Dewatering System includes only 3 % of solid material. At the end of the sludge dewatering unit, slugde includes 22 % of solid material.During the process some chemicals are added into the sludge. By using these chemicals, The amount of water in the sludge is decreased. Sludge covers less volume and can be carried more easily.

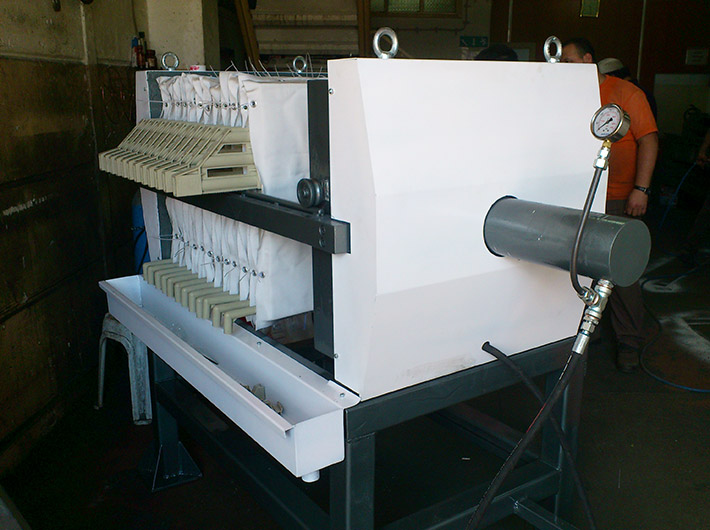

Filter Press

In filter press systems, solid-liquid mixture of the sludge fed by high pressure pumps filtered through the filter cloths on the press plates then solid particules are gathered between the filter plates and liquid part is removed from the filter press system.

Filtering cloths used in filter press equipment can be polypropylene, cotton, staple fiber or a different material depending on the physical and chemical properties of the solid-liquid mixture.

High pressure pumps thad feed filter press can be selected from among air diaphragm pumps, monopomps, gear oil pumps or lobe pumps. Centrifugal pumps are not preferred in filter press systems.

Belt press equipment have better dewatering percentages than decanters which are accepted as equivalent of the Belt press.

Plates having high hydraulic pressure are fed by pumps having high pressure.

Accumulated solids between the plates are removed after opening the plates.

The need of cake discharge system is designed as manual or automatic according to the demand of the customer.

Filter press is used not only in treatment facilities but also in mining sector, oil filtering, marble industry, chemical industry, silicate sector, coating sector (acid filtering in zinc - phosphate bath) and the other sectors.

Filter press is divided into three categories according to plate compression features;

- Manual

- Half automatic

- Full automatik

Filter press is divided into three categories according to plate features;

- Chamber type plates

- Full – empty type plates (frame - plate)

- Chamber + membrane plates

Full – empty plates are preferred generally in oil filtering sector (olive oil, sunflower oil, industrial oil etc.), food sector and petrochemical sector.

Chamber type plates are used in the filter press units of mining sector, marble treatment systems, treatment facilities, zinc phosphate coating sector and etc.

Filter press cloths have vital importance in filtering process. That’s why, the selection of the filtering cloth must be made correctly. In order to increase lifetime of the filtering cloths, Filtering cloths must be washed with pressurized water regularly.